We sat down with Chairman and CEO of FP Corporation, Mr. Morimasa Sato to discuss his firm’s dedication to adapting to food culture changes, prioritizing customer satisfaction and promoting environmental management.

If we could start by having you introduce your company. What kind of firm is FP Corporation? What are your main strengths and core competencies that allow you to stand out among your competition and what are some of the key milestones that have come to define your business throughout the years?

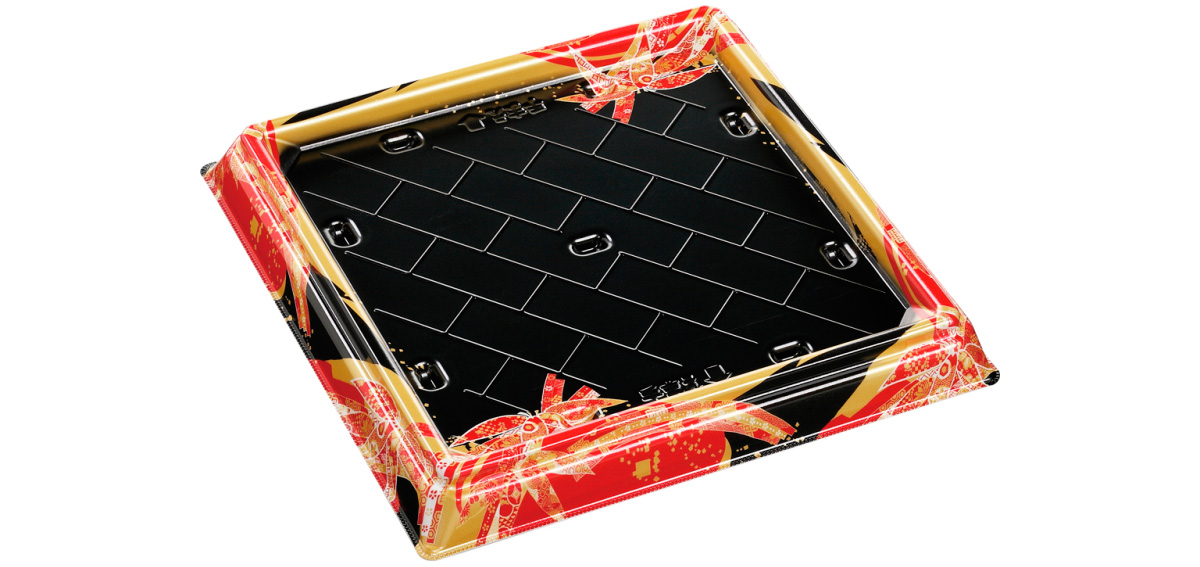

FP Corporation is a company that has been manufacturing and selling plastic food containers since 1962. The business model of FP Corporation is based on Japan’s dietary culture as well as the culture surrounding trays (foamed PS meat trays) and containers. Japanese people visually sense the freshness of food and people tend to visually enjoy food as much as actually eating it. If you go to an inexpensive bar where they use cheap-looking plates, you will notice a huge difference when you compare to a high-end restaurant where they will surely use nice-looking plates or trays to serve food. At a high-end restaurant, just by looking at the food presented, people can enjoy the sense of deliciousness. As part of Japan’s gift-giving culture, sometimes people send gifts such as high-end Wagyu beef contained in a decorative wooden box. When people look at these high-end gift boxes, they can immediately tell the food will taste exceptional. Depending on the type of gift or souvenir people give, the type of container will be different.

If you go to a supermarket, you can see on the sales floor the different types or patterns of trays used for each different type of food. For example, different trays are used for expensive beef when compared to inexpensive beef. You can witness function and effect, and I believe that only in Japan can users be so affected by the visual packaging of food. Japanese people are able to get a sense of the freshness, volume, and seasonality of their food just by observing it.

You mentioned this phenomenon only being present in Japan, however, I believe this is starting to change a little bit overseas. Your business is based on Japan’s food culture, and it is fair to say that nowadays the West has a certain fascination with Japanese food culture. What role do you believe the FP Group will play in exporting this kind of food culture overseas?

Let me use a sushi tray as an example. If sushi is placed on a completely white tray, it doesn’t create an oriental sense, so we export certain designs or patterns on our trays overseas. Still, however, there is a difference between Japan and all those countries where we export our trays. Once certain designs of trays are adopted overseas, they will hardly be changed for a long period of time. If we go back to sushi, I can explain what I mean. When the fish price for sushi or sashimi becomes more expensive because of market conditions then oftentimes the content gets smaller to adjust to the market conditions. In this situation, the container or tray needs to change too because smaller portions will not look good in the same sized tray. In Japan, the tray size is adjusted with the food portion size in order to make things look the same size when adjusted.

Seasonality also comes into play and because of Japan’s food culture, the colors of the trays need to be changed in order to match the season. We have more than 10,000 individual items, however, Japan is pretty much the only country in the world that is compatible with this kind of tray or container culture. No other market makes these kinds of adjustments to containers or trays. On the other hand, however, we believe there are techniques or technologies that can be exported overseas such as technology for leak-proof containers or microwavable containers. We engaged in an M&A activity in Malaysia and suppose that we can utilize these technologies there. It has allowed us to gain a foothold in the Southeast Asian market and start to cultivate this market. Furthermore, we believe there are other know-hows that can be leveraged there.

Our company has plants across Japan that produce approximately 11,000 items and we as a company often forecast when, and how many of our trays and containers are going to be sold. Based upon those projections we can adjust our production plan to produce according to the predicted volume needed. Through this approach, we have been able to minimize costs while utilizing our intra-supply chain management techniques. It has allowed FP Corporation to never run out of stock for an item, but at the same time not keep excessive inventory. However, the approach must be differentiated from our approach domestically because overseas markets do not really require so many kind of items.

Could you give us an overview of your recycling initiatives and activities, and to what degree can any single piece of material or tray really be recycled? There is a known limit to how many times the same piece of plastic can be recycled before the material starts to deteriorate. How many times would you say one of your containers can be reused?

30 years ago, around 1990, at six supermarket stores, we installed tray collection boxes at FP Corporation’s expense. Prior to when supermarkets emerged on the scene, people tended to visit specialty shops for particular products. Those looking for meat would visit a butcher and those looking for bread would visit a bakery. The style of sale was over-the-counter (OTC), so there was no need for trays. When supermarkets began to take over, large-sized sales at inexpensive prices meant there was a need for trays that could be used to ensure hygiene, but the trays would inevitably become garbage in the end. We predicted that trays would be criticized so we took preemptive action. That is why we asked those six supermarkets for permission to install our collection boxes.

Consumers who saw the recycle collection boxes started rinsing and washing their trays after use and then brought them when they next visited the supermarket so that they could contribute to the collection box. Those supermarkets where collection boxes had been installed experienced higher levels of customer traffic than usual. Neighboring supermarkets saw the increased traffic and started introducing their own collection boxes. This trend spread and now we have recycling boxes at 10,500 stores.

When recycling items, the most important thing is to think about how to collect the items that will be recycled. It is also important to define exactly what we mean by the tray and understand what people think about when we use the word tray. No matter the manufacturer, for trays, they are produced from a single kindof material, usually polystyrene. That is why polystyrene trays that are recovered can be recycled into a new tray once again.

If we continue to recycle only the same trays, deterioration will occur, but the trays we actually collect include trays made from virgin materials.

On both sides of the recycled trays, 25 microns of virgin polystyrene film is applied. Also, we collect other firms’ polystyrene trays which are manufactured with 100% virgin material along with ours. Because of those newly introduced virgin material, we have yet to face degradation issue at this time.

In 2001 we started collecting transparent oriented polystyrene (OPS) containers . 50% of what we recovered was polyethylene terephthalate (PET) while 30% was OPS. As OPS is a type of polystyrene it can be recycled back into a tray. PET to PET recycling was introduced in the US and Europe based upon the technology that allows for the recycling back to food-grade containers. At FP Corporation we are recycling PET bottles and containers into these transparent containers. Ratio of collected weight of used products to weight of products sold by the Company is 44%.

The bottle-to-bottle concept has already been adopted in Japan, and at supermarkets, people purchase various merchandise such as PET bottles and trays. Some of those bottles, trays, and packages can be recycled as resources. There are usually 4 types of collection boxes for recycling: separating into trays, PET bottles, cans, and milk cartons. From the consumer perspective these days, they want to know what happens to their recycling. We are letting consumers know that collected PET bottles and containers at a store are recycled back into new containers and come back to the store again. We call the concept “Store-to-Store” and spread the idea.

When recycling, the most important factor is to collect items that are possible to recycle, and that factor is why I think recycling isn’t as prevalent as it should be. Packages and containers have to be collected, and it has to be the right ones. Consumers need to understand which particular materials can be recycled and which ones cannot. In Japan, as part of the lifestyle here, people pretty much go to the supermarket daily, so it is part of their daily habit to use packaging, rinse it, dry it, and then bring it back to the supermarket for recycling. Japanese people cherish the environment, and they are also attentive to details. Japan seems to be the only country that has been successful in collecting large amounts of items for recycling. In European countries, PET bottle recycling has been successful, but for other items, they normally end up in trash cans.

You’ve successfully implemented recycling schemes in the domestic market, but applying such recycling schemes in other markets is going to be a big challenge, especially in some of the markets you are entering such as Malaysia and Southeast Asia. How are you going to bring this scheme to new prospective clients in new regions like Southeast Asia?

It is only very recently that we conducted M&A activities in Malaysia, so we are still not familiar with the customs and habits of Malaysian consumers. My sense tells me that it might be quite difficult to have Malaysian consumers wash, rinse and dry trays just like Japanese consumers do as there hasn’t been the custom to do so in Malaysia.

At our firm, we are working on the next challenge which is to expand the scope of recycling. There are two types of trays: white trays and colored trays. Right now, it is only white trays that are being recycled into trays again. As the colored trays contain ink, they are not being recycled into trays, but are recycled into other plastic products by other companies at this time. Having said that, right now we are in the process of researching chemical recycling where used color trays actually go back to the styrene monomer, one step before it becomes polystyrene. I think through this process we will be able to overcome the challenge of ink.

Over the years many interesting innovations have taken place in the material sector. Innovations such as heat retention and being lightweight have been very key milestones. Can you tell us how that innovation came about for your firm?

For example, the container in photo (1) was previously manufactured of High Impact polystyrene. By switching this to foamed tray, weight can be reduced. In addition, it has been difficult to thermoform foamed trays in sharp shapes, but technological innovations have made it possible to thermoform sharp shapes such as those of Highimpact polystyrene.

Which particular markets overseas do you believe will be best received?

This has been developed with the Japanese market in mind so for right now the focus for this product is the domestic market. Looking at our supermarket client, so we believe that what we have developed will be impactful when it comes to achieving the reduction of plastic use.

Imagine that we come back in 5 years and have this interview all over again. What goals or dreams would you like to have achieved by the time we come back for that new interview?

Looking forward 5 years from now I imagine a world where we will have acquired almost 100% market share in trays because of the CO2 emission issue. Trays that are not eco-friendly will not be used by supermarkets because they are becoming quite conscious of the environmental impact these days. The “Store-to-Store” concept I mentioned will be more widely adopted. For Southeast Asia, using our elemental technologies we will have enjoyed growth in those markets. The way we conduct business there however will be different from how we conduct business here in Japan.

0 COMMENTS