With expertise in machine tool peripheral equipment specialized in chucking, rotating, and holding technologies, Matsumoto Machine offers its clients integrated solutions to improve factory productivity and efficiency.

“We find joy and satisfaction in solving our customer’s problems. It has led to inventing dedicated peripheral equipment for a wide variety of workpieces.”

Kaname Matsumoto, President, Matsumoto Machine Co., Ltd.

When it comes to factory machinery and automation solutions, Japan still rules the roost thanks to small, agile and innovative companies like Matsumoto Machine, which supplies chucking solutions, rotating solutions, holding solutions, special parts, element parts, and system integration to its manufacturing clients.

In 1948, Eiichi Matsumoto established the company with a mission to increase productivity and enterprise value for its clients. Seventy-five years on and that mission still guides Matsumoto Machine and current president Kaname Matsumoto, with the company at the forefront of developing factory automation and robotics solutions for Japanese companies facing an ever-increasing shortage of human operators due to the nation’s aging population.

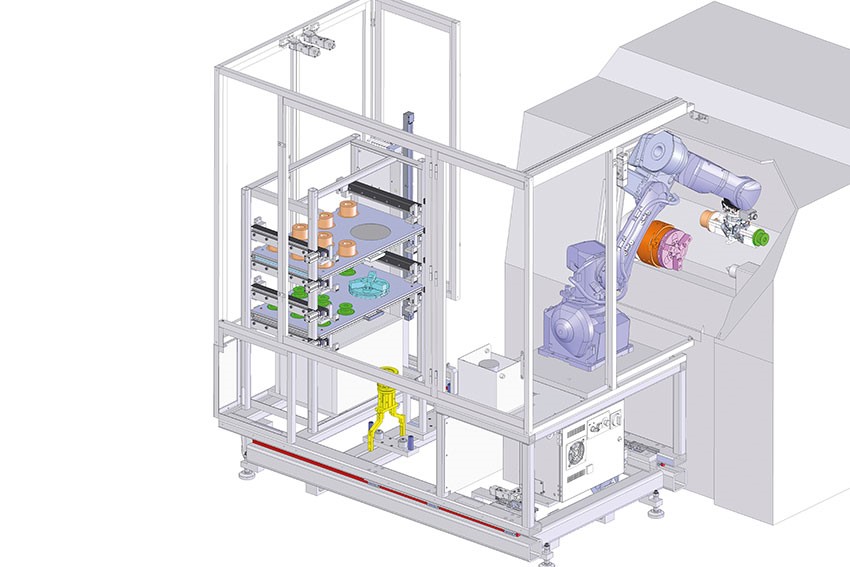

“Production line efficiency and robot utilization are the main business for us right now. By analyzing the functions of automation in manufacturing, new ideas can spring forth,” says Mr. Matsumoto. “Matsumoto Machine already has a proven track record for system integration for customers’ existing production lines. In the future, I see an escalation in this segment and we are looking positively at system integration and factory automation.”

Among the latest solutions developed by Matsumoto Machine are ROBO-QJC, an automatic chuck jaw replacement system, and Smart Terrace AIO, a one-stop solution that makes use of the company’s extensive experience and for which Mr. Matsumoto sees applications for clients in several industries. “It is used in the metal machine processing industry, however, I would say that we are looking to diversify that and the equipment can be utilized in a number of different applications.”

In terms of global expansion efforts, Matsumoto Machine has grown its customer base in the U.S. since it established a presence there in 1989, and aims to find more international partners that can support its ambitions to bring Japanese monozukuri (manufacturing craftsmanship) to more clients around the world.

0 COMMENTS