Cracking open the conversation about egg farm automation, we unveil a Japanese manufacturer's cutting-edge egg solutions, and that’s no yolk.

Japanese manufacturing is at a very exciting time. The past three years have seen large supply chain disruptions due to COVID and the US-China decoupling situation. As a result, many corporate groups are looking to diversify their suppliers for reliability. Known for their reliability as well as advanced technology in specialized and niche fields, Japanese firms are in an interesting position. Due to the weakened yen, observers argue that this is a unique opportunity. Do you agree with this sentiment? What are the advantages of Japanese companies and specialized manufacturers like yourself in this macro environment?

We basically followed Europe and the US in terms of automotive production because our automotive development started in those places. Because Japan followed suit, companies like Toyota, Nissan and Honda were born. Similarly, I think, Egg Farm Automation (EFA) originated in the US 60 years ago, which chased after volume quantity and automation. When Europe came after the US, they worked on providing a better environment by eliminating odor, flies and pests.

We partnered with one of EFA manufacturers in Germany for 23 years since 1986, but we had different opinions on two things. A vertical cage has several cage layers in one building. Since Japan often experiences earthquakes, EFA in 3 houses with a capacity of 200,000 eggs per day, collapsed 16 years ago just after the installation. Despite the disaster, our customer paid the equipment. However, our partner was not very cooperative, and we did not see eye to eye about the earthquake resistance system. We needed to develop an anti-earthquake system by ourselves. EFA started in Japan 40 years ago, after the US and Europe, while South Korea began 30 years ago. We wanted to set up a joint venture with our partner in China to manufacture EFA, considering that it was cost saving to transport everything from Europe. Since our partner was not supportive of this idea, we concluded our partnership with them in 2009.

Our major competitor is one of EFA suppliers in EU , which used to have a larger market share in Japan. Today, we take more than 60% of the market share. Rather than competing in terms of price, we gain a competitive edge through our EFA performance. Our slogan, "CF(Challenge Future) 80," indicates our target of gaining 80% share of Japanese EFA market in the future, bearing in mind that our staffs possess the artisan trait of improving everything in the performance and the quality.

Western countries introduced many developments in other sectors such as computers, software like Microsoft and e-commerce, Amazon & GPT. While they are highly innovative and leading the world, Japan continues to take the lead in manufacturing and engineering. Other inventions like drones originated from the West, but I believe that Japan can catch up.

Hytem has developed the most advanced egg collector in the industry which can significantly reduce cracks or even outright get rid of them altogether. Can you tell us how you developed this egg collection system ?

The impressively low crack rate in the automatic collection process compared to our competitors makes our system special. Looking at the entire picture, we always have few percents cracks in cages, because laying birds(birds) hit eggs. Meanwhile, HYTEM egg collector almost has a zero crack rate in the automatic collection process.

There are two major reasons for HYTEM egg collector has the ultimate zero crack rate. Firstly, cages have several layers in a building, and we use an elevator to transport eggs from each layer to one level, the centralized main conveyor by 100% traffic control , by which definitely no collision among eggs in multiple layers' cages. Secondly we employ a horizontal rolling out of eggs to the centralized main conveyor from the elevator. On the other hand, our competitors' rolling out system is sloped by which eggs get speed, incidentally which creates the higher crack rate.

What are other strong points of HYTEM EFA?

We are presenting 10 strong points including the above mentioned ultimate zero crack by automated egg collection. Let me refer the second points, a new Rats-Free system.

Rats are the real headache of the egg farm that carry pathogens and come after the feeds that are fed to birds. The recent advanced egg house is perfectly air-conditioned with no windows. However there are two openings where rats come in, the openings for the bird manure conveyor and the egg conveyor. 5 years ago, we developed a system to seal the egg conveyor opening perfectly. Moreover, we also created a system to seal the bird manure conveyor 2 years ago.

How is strategy to guide your customers to select HYTEM EFA ?

We are asking our customers' understanding in 2 Groups Purchasing Policy to earn in

egg farm operations. Purchase as low price as possible, such items as materials which can be changed the next month. And, purchase EFA by the performance since it cannot be changed for more than 20 years once purchased.

For the performance, we are presenting Profit No.2&3. Profit No.1 in the basic profit of egg farms involves how high they can sell eggs and how cheap they can buy feeds. This is a fundamental profit in egg farming. Profit No.2 comes up when they start automation. If you buy a 100,000 birds house at USD 20 per bird, then that would be USD 2 million. The study of the equipment price considers how much it is per bird. With that in mind, our equipment is more or less USD 20 per bird. It would be USD 2 million for 100,000 birds. Our average sales for each customer is around USD 0.5 or 1 million . A 2% difference in the crack level would mean a USD 7 per bird difference in 20 years. A 2% difference in feed efficiency without any rats or by the warmer house temperature in the colder season, which would be another USD 6 per bird difference.

When the ventilation is the better, the egg production may improve by 1%, which would generate USD 5 per bird difference. Our equipment is quite reliable, then, our clients will get another five years of service, which would be another USD 4 per bird difference. The total of Profit No.2 could be USD 22 per bird, which is the bigger amount than our equipment price, more or less USD 20 per bird.

Profit No.3 will be generated by the better management of the egg farm. When the egg farm run well supported by the better EFA after sales services, another 1% better per bird egg production could be expected, which will bring further USD 5 per bird to the egg farm.

Sometimes the investment for semiconductors in the electronic industry could not work anymore after 10 years. This kind of calculation is difficult. Nevertheless, since the demand for eggs will continue after 20 or 30 years as long as humans exist, Profit No.2&3 formula could steadily work.

In the Chinese market, where EFA is now fully starting, there are more than 30 domestic EFA manufacturers, besides EU suppliers which have already been there for 15 years. In Chinese EFA market, domestic manufacturers’ price is quite low. Even if theirs is half than our price, it would still be USD 10 per bird. We are expecting that progressive egg farms will select HYTEM paying attention Profit No.2&3 which could bring them more than USD 20 per bird.

How is your strategy to manufacture ?

Our strategy to manufacture is all R&D, including designing, manufacturing drawing and quality control by our headquarters at Kakamigahara city in the greater Nagoya area, which called Headquater Factory even though there are no equipment to manufacture. In manufacturing, R&D, designing, manufacturing drawings and quality control are key. We set up our manufacturing factory in Tianjin because we need to comply with the row price requirement of EFA. Normally, our egg farm automation's price is, as other agricultural equipment, half of the conventional factory equipment in extreme. We may find the same kind of an example in electric products. The price level of Hitachi's power generation equipment is double that of TVs or other electronic products for home use. The labor

in Japan is too expensive to allow us to be competitive in EFA cost. We started our factory in China in 2009, locating in Tianjin because the Toyota head factory is there. It takes three to four hours from Nagoya to our factory. With Toyota being there, there is more influx of Japanese industries.

Our drawing is along by JIS (Japanese Industrial Standards). Screws or sheet metals are all by JIS, making those parts easier to obtain in that area. We own 100% of our manufacturing in China, and all our staffs are Chinese, including factory managers. Our company philosophy is to work hard for a better salary that you can be proud of. Also, in China, we are trying to provide as good salary as possible, and I hope it is working.

How do you plan on evolving your egg farm automation systems going forward? Could you share your R&D strategy with us? Is there anything you are working on that you would like to showcase to our international readers?

There are two major R&D themes we are working on for the future. One is Egg Farm IoT, and another is to minimize Avian influenza risk.

As Egg Farm IoT, through our existing technology, we can obtain significant information like temperature, quantity of feeds, amount of water and egg production per row in a house. However, we still need to gather other information, such as the egg weight per house and the bird weight. Currently, we get egg weight at the packing stage, but we would like to identify which house has a better egg weight. Co-research was done with Aichi Institute of Technology and the Aichi Agricultural Research Center, and we completed the development last year with one of Kyoto University venture companies. At this stage, we have deployed that into two farms and are obtaining more than 99% accuracy.

As for the birds weight, which currently manually inspected taking hundreds birds weekly, the automatic weighing system has been developed by our R&D by which daily weighing proceeded while birds are sleeping, and currently under the field test. The third IoT R&D project is to find dead birds. When by 100,000 birds house, around 10 birds die every day due to diseases or stress, which is currently visually inspected, but it is hard work sometimes with overlooking.

We are developing the dead birds AI finding system with more than 99% accuracy with miss-judging percents(recognize a live bird dead) less than 5%, under a joint R&D with one of major Japanese electronic companies and one of major egg farms.

All above information can be centralized at the egg farm office and/or the headquarters when necessary through the cloud system. The production key staff and farm operators can monitor the screen to identify whether everything is going smoothly, and able to take quick optimum actions.

The second major R&D is equipment wise to minimize Avian influenza(a bird flu pandemic) risk which is becoming worldwide issue. 2 channels are recognized as a cause of the outbreak.

One is rats and vermin contaminated by wild bird droppings with Avian influenza bacteria coming into the house . This can be prevented by the Rats-Free system referred in the fore going.

Another is outside air coming into the house with Avian influenza bacteria.

We are on the way to find the most cost effective and practical approach to control the bacteria in in-coming air, cooperating with the academia research.

Do you know when the egg farm IoT system will be launched?

We do the usual R&D as in-house development. When R&D reached the materialized stage, we conduct field testing for half to 1 year at the farm in this area that produces half million eggs per day. If everything is good, we will go into the pilot sales. Our IoT system, HYTEM Egg Farm TIS(Total Information System) pilot installation is being proceeded at one of million birds egg farms in Japan.

Considering that Japan’s borders have opened and the pandemic has died down, many companies in Japan are looking toward exhibitions as a way to promote their activities, get new products and make new connections. Is participating in international exhibitions an area of interest for Hytem?

Our sales strategy is to sell directly to egg farms in Japan and China, and have one sole distributor in the other Asian countries. Following the concept of having a sole distributor as a partner instead of multiple distributors in one country eliminates the need for us to make adjustments among plural distributors in one country. Its advantage is that we will not need to hire more staffs. However, the disadvantage is that we lose customers if our products fail to keep their competitive edge over our competitors. In our experience, it will work as long as we keep our products’ strengths.

HYTEM sole distributors are in Korea, Taiwan, Philippines, Vietnam, Thailand, Indonesia, Bangladesh, India and Pakistan. Some of these have an active development. It depends on how EFA is progressing in each country. We are not pushing. We are satisfied as long as they remain enthusiastic to promote HYTEM EFA. Our policy will concentrate on Asia, where 60% of the world population is. Some EU EFA suppliers are selling all over the world, but our target is to be the leaders of EFA in Asia.

How do you plan on targeting Asia?

The potential market is related to its population. Since its population is 20 times that of Japan’s, the market is also 20 times. In Japan our strategy is CF80, which targets 80% market share. For the other Asian countries, averaged 10% market share is our goal, meaning we have two times the potential sales volume in Asia than in Japan. It also means we aim to sell our equipment to the top ten 10% progressive egg producers, who are more concerned about the performance and the quality understanding HYTEM Profit No.2&3 advantages.

We are participating three EFA shows in total.

One is an exhibition in Nagoya every 2 years. The others are VIV Asia, every 2 years which is the most popular EFA show in ASEAN countries, and the China Animal Husbandry Expo (CAHE) held every year in a major city.

In each country HYTEM sole distributor, like Bangladesh and Philippines, takes responsibility for its exhibitions. We just support them when they need some equipment.

Imagine we come back in 4 years for your 55th anniversary. What are your goals? What would you like to achieve in the next 4 years?

Last year, we had a party to celebrate our 50th anniversary, where we announced our three targets for the coming 50 years.

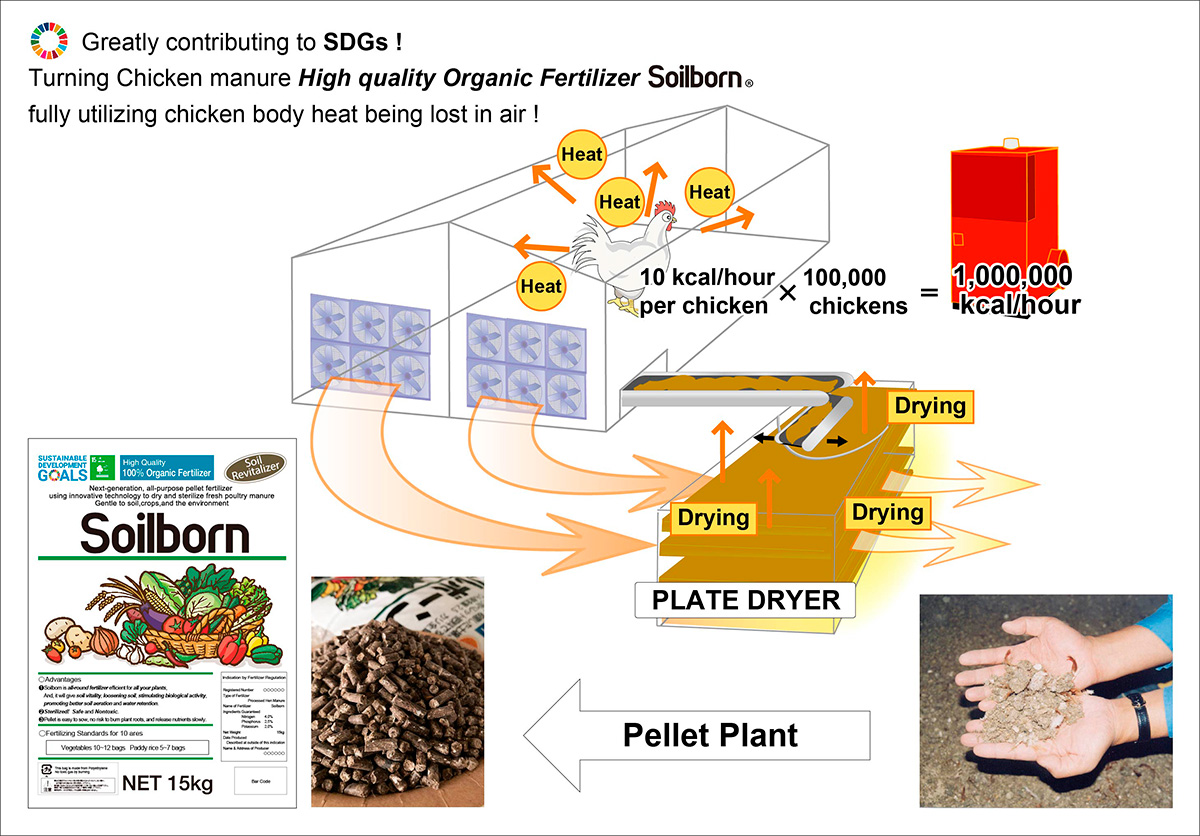

The first is the more high-level utilization of laying hen manure. We started research with Gifu University in 2013, targeting laying hen fresh manure into the high quality organic fertilizer. Our strategy is to produce a high-quality organic fertilizer under Soilborn brand, with the solid quality standards. For example, with the guaranteed N, P and K contents achieving a moisture level of 10% maintaining the desired pellet hardness .

Production of Soilborn

Soilborn brand has already been registered in Japan and almost all Asian countries, which will be granted in actual cost basis to egg farms which have established Soilborn production under above mentioned quality control. This Soilborn is currently being produced at an egg farm in Tokyo area, which produces yearly 10,000 tons. We must promote Soilborn, the organic fertilizer for Japanese agriculture to go along with the governmental program, Green Food System Strategy, one of which is to reduce the chemical fertilizer by 30% until 2050, replacing by the organic fertilizer which enhances dry soil strength. The total organic fertilizer required will be more than yearly several million tons. In other Asian countries, we are expecting far more sizable Soilborn market .

Moreover, Soilborn development, I believe, will greatly contribute to SDGs progress.

The second is HYTEM LHS(Layer House System). Under the circumstance that EFA is becoming more systemized and more standardized, building is better more systemized and more standardized targeting the better quality with the reasonable cost.

The basic scheme has been almost completed, and the program will be progressed step by step, cooperating with our users and with our sole distributors in Asian countries.

The third is the need for one more factory, and we are looking at India. However, India's EFA development is slow and just starting. To start production, we need demand. Still, this is what we need to do in the long run.

What is your opinion on Laying hen Animal Welfare ?

International standards of Laying hen Animal Welfare(AW) was failed to be established at OIE(World Organization for Animal Health) general meeting held in May 2021 by different opinions between those countries with 90% world population whose egg production is mostly by cage systems and EU countries with 10% world population whose egg production is mostly by floor systems.

I think, AW standards should be established standing on the egg production field to maximize consumers' advantage under the most desirable and realistic balance between the egg production and the ethology(the animal behavior science).

As far as egg production and egg quality level concerned, Japan is located at the top in the world, that is, we can say, Japan is Egg Kingdom. The best taste of eggs can be experienced by "Tamago Kake Gohan(raw fresh egg on rice)" as the best taste of fishes can be experienced by Sushi and Sashimi.

To produce safe and security eggs edible in raw in the most efficient way in the cleaner house air (less dust) and workers friendly environment is, in our EFA supplier point of view, it is the most advanced cage systems which are being used at major egg farms in Japan.

As major EFA supplier in Japan, HYTEM is supplying floor systems as well. However, as EFA for majority of world countries with 90% world population , at least for Asian countries where with the higher population densities and with the higher humidity in summer time, incidentally with the higher diseases risk, establishing AW by cage systems without the nest & the perch which provide the cleaner environment without the hidden places, separating the laying hen from manure, is required and realistic.

In this background, in my opinion, two AW standards, AW by cage systems without the nest & the perch and AW by floor systems with the nest & the perch are required to be established.

Interview conducted by Karune Walker & Sasha Lauture

0 COMMENTS